Date: January 21st (Wednesday) – 23rd (Friday), 2026 10 am – 5 pm

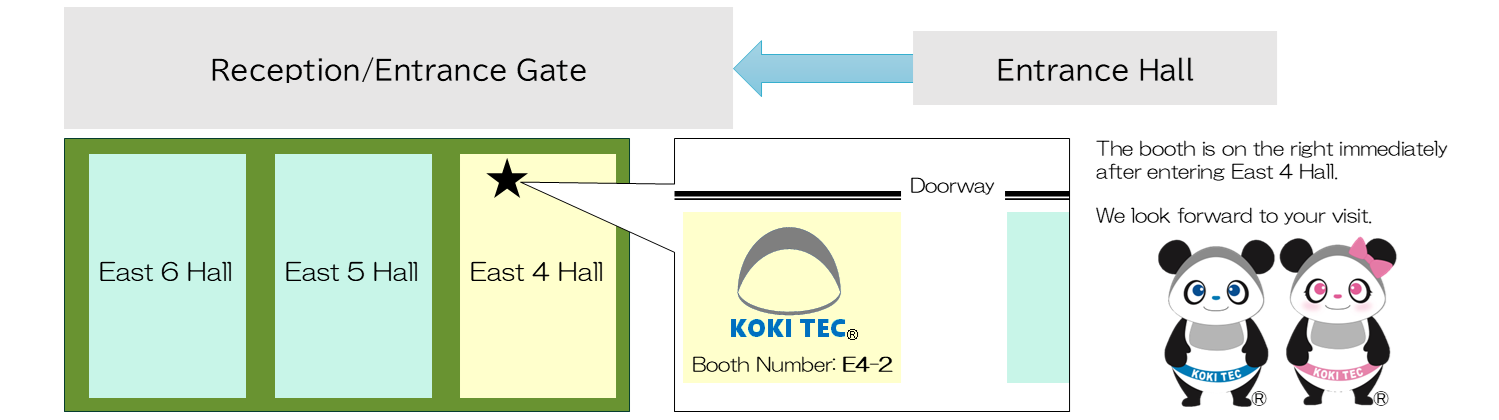

Venue: Tokyo Big Sight Exhibiting booth of KOKITEC CORP.: East 4 Hall E4-2

Information about visitor registration

Please register using the QR code or via the website below.

Machines to be exhibited

Selective soldering series

■Benchtop/All-in-one type

Exhibiting newly designed “ULTIMA – TRZⅡ/SPZⅡ/NEO-L316” with new colors

■Inline type

Next-generation soldering process will be shown in SELBO III module as reference exhibition

Productivity improvement, traceability

Also exhibiting productivity improvement items such as automated start-up inspection (Dr. Pallet) and tracer (Soldering EYE)

Inspection and measurement inspection machine series

■3D visual inspection machine (RV-2-3DH)

Aggregates functions necessary for inspection processes on mounting lines

Multi-platform inspection machine compatible with SPI, AOI, and moisture-proofing agent application methods

A wide range of options are available for quality and process control

■Non-mounted inspection machine (SE100 + collaborative robot)

“The challenge of being flawless”

Achieves automated visual inspection of machined products with an 11.5μm resolution monochrome camera

Examples of combinations with collaborative robots will be shown

■Micro-defect inspection machine

High-speed 2D inspection and high-precision (1 μm) 3D inspection

Provides the best solution for bump/pattern inspection etc.

2D inspection resolution selectable from 1.1μm/0.55μm/0.275μm

3D inspection resolution XY: 1.2μm/Z: 0.02μm

Exhibition booth information