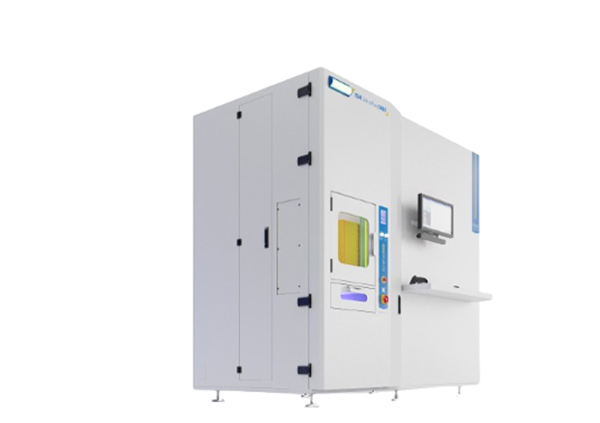

SPARK-CD II

This laser marker enables simultaneous printing on both sides of a PCB.

The laser unit is equipped with a Z-axis, allowing it to accommodate different thicknesses of PCBs and components.

The dot size is 0.11mm for CO2 lasers and 0.04mm for UV lasers, allowing for high-resolution marking.

(Manufacturer: JUTZE Intelligence Technology Co., Ltd.)

| Laser type | CO2 (dot size 0.11mm), 5W, forced air cooling |

|---|---|

| Drive method | XY-axis drive, Rail width auto adjust mechanism |

| Outer dimensions | W1050 X D1300 X H1960 (mm) |

| Applicable PCB size | 50 x 70 mm ~ 470 x 350 mm |

| PCB clearance | Top side 30mm / bottom side 30mm |

| Weight | 900Kg |

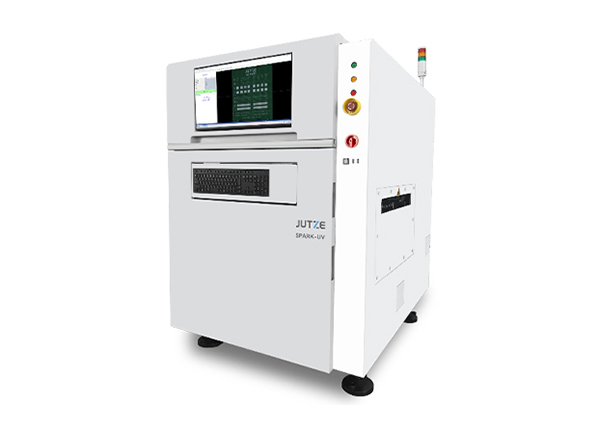

SPARK-UV

| Laser type | UV (dot size 0.04mm), 5W, water cooling |

|---|---|

| Drive method | XY-axis drive, Rail width auto adjust mechanism |

| Outer dimensions | W1100 X D1540 X H1880 (mm) |

| Applicable PCB size | 50 x 70 mm ~ 510 x 460 mm |

| PCB clearance | Top side 30mm / bottom side 30mm |

| Weight | 1050Kg |