Maintenance and Inspection Unit

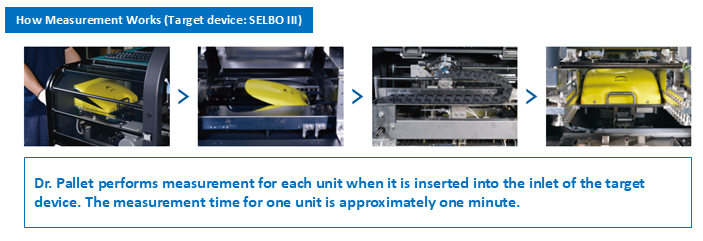

Automatic Adjustment Unit for Selective Soldering Machine (Dr. Pallet)

Automates adjustment of nozzle position (reference position)

Automates inspection of nozzle shape abnormalities

Inspects wave roughness of flow by checking it from above

Saves inspection data as traceable images

Automatic wave height adjustment function (option)

(Manufacturer: KOKI TEC CORP.)

| Outer Dimensions | L330 x W250 x H110(mm) |

|---|---|

| Power | Lithium-ion battery 76 Wh DC 18V/2A (Charging adapter) Can be used continuously for 2 hours on a single full-charge |

| Weight | 4kg |

| Applicable Models (planned) | ・SELBOⅡ/SELBOⅢ・CBSS-6060A・ULTIMA-NEO-L 316 ・ULTIMA-TRZⅡ・EQS(Height restrictions applied to some components) |

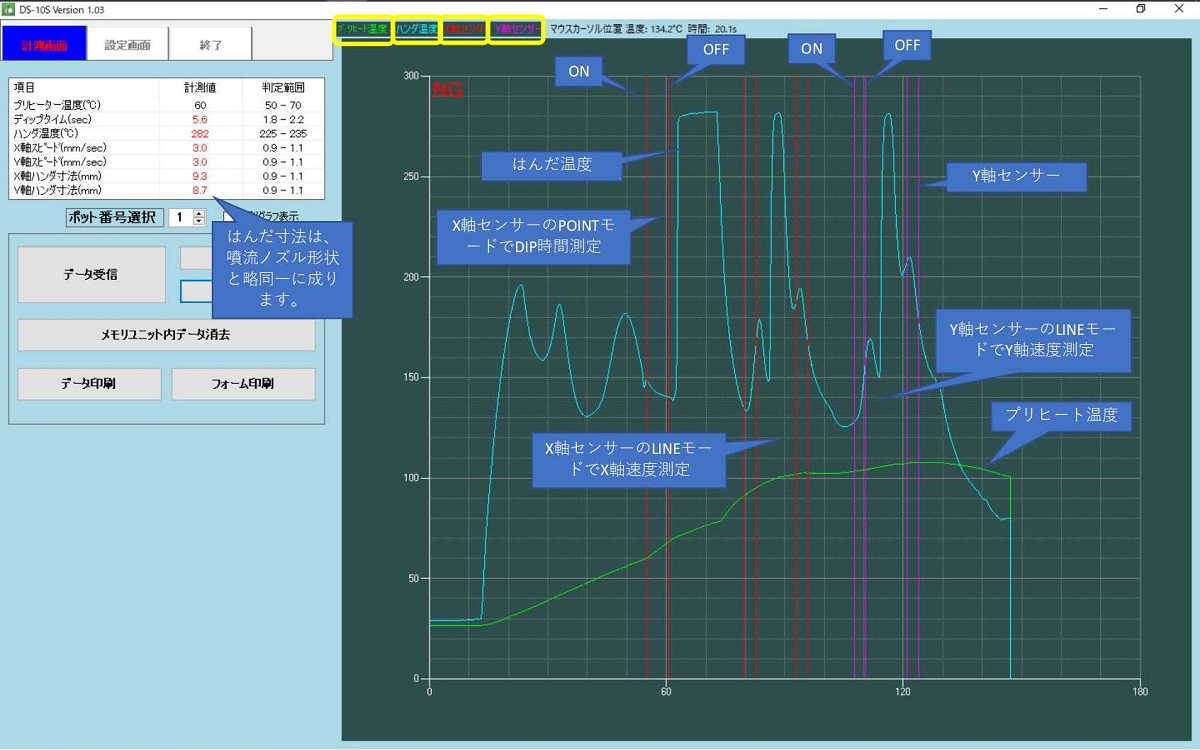

“DS-10S”, Dipping Tester exclusive for a Selective Soldering Machine

Malcom Co., Ltd.

Equipped with the features useful for management of a point soldering machine

1. Preheat temperature measurement function (it virtually displays a temperature of the preheater as a PCB surface temperature)

2. Measures and displays a soldering time (ON/OFF of a X-axis sensor is used for measurement)

3. Measures and displays a soldering temperature

4. Measures and displays a XY-axis speed

5. Measures and displays solder contact width on a XY-axis operation (the sensor passing time and speed of XY-axis is used for calculation)