Insertion Machine

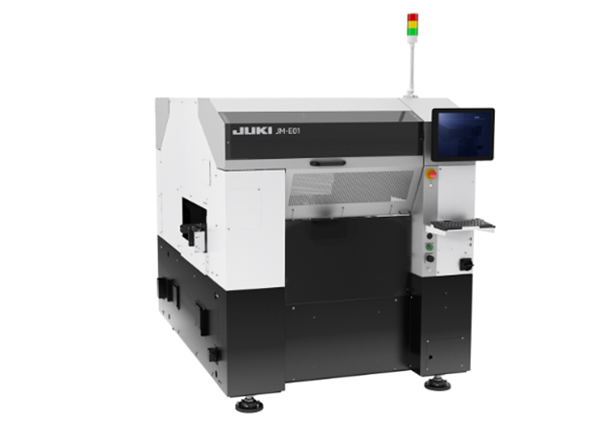

Multitask Platform (JM-E01)

This highly versatile machine realizes component inserting work, screw fastening work, and multi-process automation. The board size is 800mm x 560mm*¹,and the weight is up to 10kg*².

A versatile platform that consolidates various insertion processes, allowing space savings by replacing specialized machines with a single, general-purpose unit.

XY shaft construction adopted. By setting head unit axis to 2 axes, the compatible component size has been expanded.

(Manufacturer: JUKI CORPORATION)

| Board size(mm) | Single clamping:50×50~410×560 Double clamping:50×50~800×560 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PCB weight | 6kg(standard)10kg(option) | |||||||||||

| Component height | Component body 80mm or less, lead + body = 90mm or less | |||||||||||

| Component size(mm) | Outer dimension (package) size 150mm Recognition size once:40×25, 4×1:150×25, 4×2:150×48, 4×3:150×71 |

|||||||||||

| Applicable screw size | M3 size*2 | |||||||||||

| Screw supply method | Force-feed type | |||||||||||

| Machine dimension(mm) (W×D×H) *1 | 1,500×1,930×1,600 | |||||||||||

| Body weight | 2,000kg | |||||||||||

*1 For 900mm conveyor

*2 Please contact for detail

Multitask Platform (JM-100)

Best in class speed. Component insertion time down to 0.6 seconds for vacuum nozzle and 0.8 seconds for gripper nozzle.

New “Takumi head” with multiple recognition heights

Component Feeding

Line control using JaNets software

(Manufacturer: JUKI CORPORATION)

| Standard specification (Lsize PWB) |

Clinch specification (Lsize PWB) | ||||||

| With using Clinch unit | Without using Clinch unit | ||||||

| Board Size | 1 time clamping | 50mm×50mm~410mm×360mm | 80mm×100mm~410mm×360mm | 80mm×50mm~410mm×360mm | |||

| 2 times clamping | 50mm×50mm~800mm×360mm | 80mm×100mm~800mm×360mm | 80mm×100mm~800mm×360mm | ||||

| PCB Weight | max.4kg | ||||||

| Component Height | max.30mm | ||||||

| Component Size | Laser recognition | 0603~50mm | |||||

| Vision recognition | 3mm~78mm×48mm or 85mm×25mm | ||||||

| Insertion Speed (Insertion components) | Vacuum | 0.6 sec/part*1*3*4 | |||||

| grip | 0.8 sec/part*2*3*4 | ||||||

| Placement Accuracy (SMT) | Laser recognition | ±0.05mm(3σ) | |||||

| Vision recognition | ±0.04mm | ||||||

* 1 Specification conditions

(Applicable part: Aluminum electrolytic capacitor (φ 8 mm), Feeder: two MRF-S, Placement conditions: Simultaneous pick, sequential insertions using 2 nozzles)

* 2 Specification conditions

(Applicable part: Connector (4 pin), Insertion conditions: 2 sequential picks and insertions using 2 nozzles)

* 3 Board transfer and mark recognition time not included.

* 4 When the part height is 16 mm.

Multitask Platform (JM-50)

Ideal for high-mix low-volume production

New, flexible feeders increase component range providing superior productivity and faster changeover

Huge variety of applications

Largest installed base thanks to high quality and unmatched reliability

(Manufacturer: JUKI CORPORATION)

| Board size | Single clamping | 50×50mm~410×360mm | |||

|---|---|---|---|---|---|

| Double clamping | 50×50mm~800×360mm | ||||

| PCB weight | 2kg | ||||

| Max. component height | 30mm | ||||

| Component size | 0603~50mm | ||||

| Power supply | 3-phase AC200~415V | ||||

| Apparent power | 2.2kVA | ||||

| Circuit breaker | Standard | ||||

| Air consumption | 81L /min | ||||

| Conveyor height | 900mm, 950mm | ||||

| Machine dimension (WxDxH) | 1,454×1,505×1,450mm | ||||

| Mass (approximately) | 1,300kg | ||||

Laser sensor for lead detection *1 Optional specification.Multitask Platform (JM-20)

Wide variety of feeder types (Feeders can be customized for specific components)

Lead 90 degree bend function

Lead Correction Unit

(Manufacturer: JUKI CORPORATION)

L-size board

XL-size board

Board Size

Single Clamp

410×360mm

410×560mm

Double Clamp

800×360mm

800×560mm

PCB Weight

max.4kg

Component Height

28mm

○

55mm

○

Component Size

Laser recognition

0603 ~ 50mm

Vision recognition*1

54mm view camera

3mm ~ 50mm

27mm view camera

1005 ~ 24mm

Insertion Speed

Vacuum (JUKI Condition)*2

0.8 sec/parts*3*4

Placement Speed (SMT)

Chip (Optimal)

15,500 CPH*3*4

IC

4,200CPH*3*4

Placement Accuracy (SMT)

Laser recognition

±0.05mm(3σ)

Vision recognition*1

±0.04mm

*2 Under JUKI condition

(Component type: aluminum electrolytic capacitor (φ8㎜), Supply device: MRF-S x 2; Two points simultaneous pick x 3 times/cycle (6 nozzles), Axis speed: Default value for component type “Insertion component” “INS electrolytic capacitor (JM-20 only)”.

*3 Excludes time for PWB conveyance and mark recognition.

*4 For component height 28mm.