Coating

In-line Solder Paste Dispenser

SD-3325

Two M-size PCBs can be coated simultaneously (double throughput)

Twin air dispenser allows for fine application of solder paste and so on

Two types of dispensers enable applying different fluids simultaneously in dual stages.

| Equipped dispenser | High-precision dispenser Twin-air®x2 |

|---|---|

| Minimum solder application diameter | 80 (um) |

| Mountable PCB size | 330 x 250 (mm) 2 sheets |

| Mountable PCB thickness | 5mm |

| Conveyor dead space | 3mm from PCB edge |

| Height adjustment of PCB | Laser displacement gauge |

| Position alignment | Auto alignment (Mark: circle or square within 3mm) |

| Nozzle cleaning | Auto nozzle cleaning and test spray functions |

| Option | Scale loader and unloader (for auto adjustment function of spray volume) |

| Air as a driving force | Clean dry air 0.4MPa |

| Power source | Three-phase AC200V max. 15A(5kVA) |

| Outer dimensions | 840 x 1200 x 1500 (mm), not including protrusions |

| Weight | Approx. 700 kg |

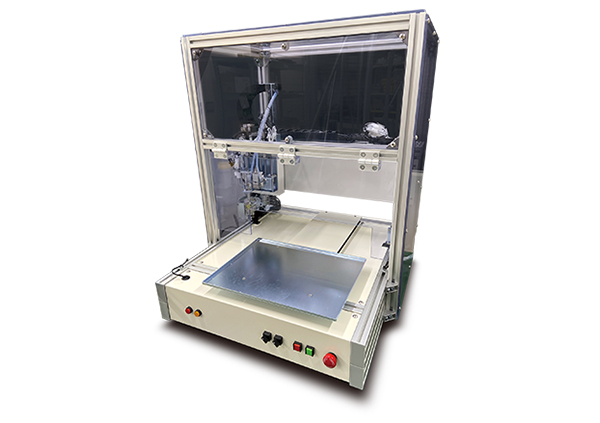

PCB Desiccant Coating System

JC-3325

Enables automatic coating even for small parts of a PCB

Two types of application heads allow for efficient coating

Forms a uniform film thickness due to no scattering outside the coating area

Dedicated software allows easy creation of coating path data

| Application head | Film coating, needle |

|---|---|

| Application direction | 0-360° |

| Mountable PCB size | 330 x 250 (mm) |

| Mountable PCB thickness | 5 mm |

| Application width of film coating | 8-15 mm |

| Application width of needle | 2-4 mm |

| Application pump | Pneumatic method |

| Nozzle cleaning | Test spray function |

| Data communication method | Ethernet |

| Air as a driving force | Clean dry air 0.4MPa |

| Power source | AC100 V 10A |

| Outer dimensions (When mounting safety cover) | 560 x 700 x 560 (mm) (640 x 856 x 786 (mm)) |

| Weight | Approx. 40 kg (main unit only) |